Intro

Manufacturing's dirty secret isn't equipment failure or supply chain disruptions. It's human error, responsible for 23% of all unplanned downtime, costing Fortune Global 500 companies $322 billion annually. While organizations obsess over predictive maintenance algorithms and IoT sensors, they overlook the most unpredictable variable in their operations: people making preventable mistakes that trigger cascading failures across production lines.

The numbers paint a sobering picture. Siemens' 2024 True Cost of Downtime report reveals unplanned downtime now drains 11% of annual revenues from the world's 500 largest companies, totaling $1.4 trillion, up from $864 billion just five years ago. In automotive manufacturing, each hour of idle production hemorrhages $2.3 million, or $600 per second. Yet despite these staggering losses, most organizations still treat human error as an inevitable cost of doing business rather than a solvable problem requiring systematic intervention.

The Human Factor: Manufacturing's Most Expensive Variable

Human error manifests in countless ways across manufacturing operations, each seemingly minor mistake potentially triggering hours or days of downtime. Operators misconfigure machines, skip critical quality checks, or fail to follow established safety procedures. Maintenance technicians misdiagnose problems, overlook warning signs, or apply incorrect repair techniques. New employees unfamiliar with equipment make costly assumptions. Experienced workers become complacent, cutting corners that worked yesterday but fail catastrophically today.

The automotive sector illustrates this crisis vividly. A single operator entering incorrect parameters on a robotic welding system can halt an entire production line producing 60 vehicles per hour. At $2.3 million per hour in downtime costs, a five-minute human error that takes two hours to identify and correct costs nearly $5 million. Multiply this across multiple shifts, multiple lines, and multiple facilities, and human error becomes a billion-dollar problem hiding behind terms like "operator mistake" or "procedural deviation."

Training gaps amplify these risks exponentially. Manufacturing faces a generational knowledge crisis as experienced workers retire, taking decades of institutional knowledge with them. Younger technicians arrive with different skill sets, often more comfortable with digital interfaces than mechanical systems. The average manufacturer now dedicates 20 hours weekly to unscheduled maintenance, much of it addressing problems caused by inadequate knowledge transfer or inconsistent training programs.

Documentation failures create another layer of human error risk. Poorly written work instructions, outdated procedures, or missing critical steps lead to inconsistent task execution. When five different technicians perform the same maintenance task five different ways, equipment reliability becomes a game of chance rather than engineering precision.

The Compound Effect of Downtime Costs

The $1.4 trillion headline figure only tells part of the story. Direct production losses represent the visible tip of an iceberg that extends deep into organizational finances. When human error stops production, costs multiply across multiple dimensions simultaneously. Labor expenses continue accumulating for idle workers who must still be paid despite producing nothing. Overtime costs spike as teams scramble to recover lost production, often at 150% of normal labor rates.

Material waste compounds these losses. When production halts mid-cycle due to human error, work-in-progress inventory often becomes scrap. A pharmaceutical manufacturer reported losing $3.2 million in active ingredients when an operator's procedural error contaminated an entire batch that couldn't be recovered. The error took seconds to make but weeks to fully resolve, including root cause analysis, retraining, and process modifications.

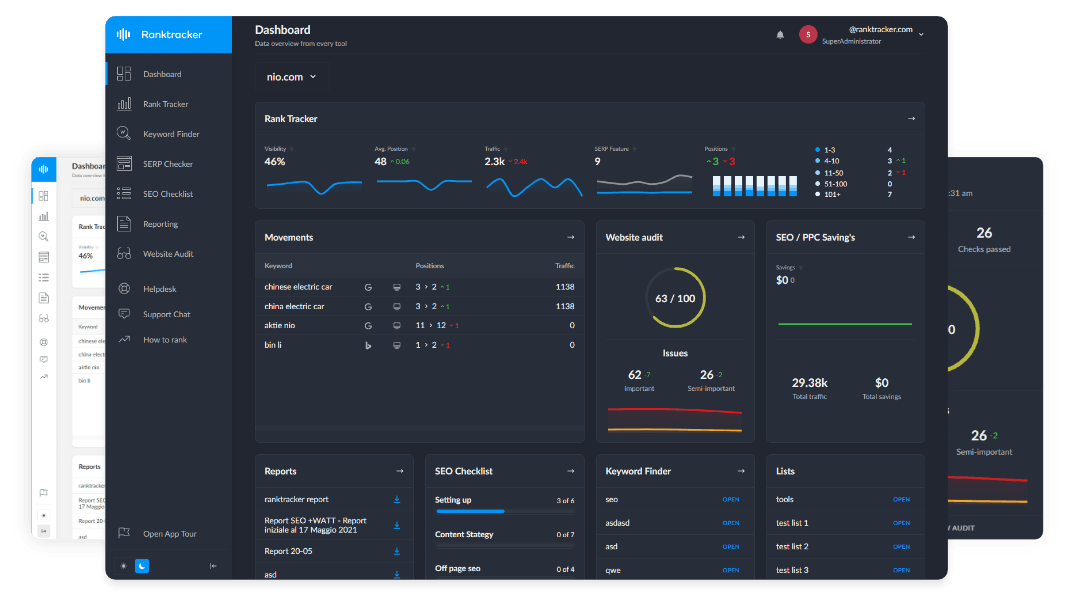

The All-in-One Platform for Effective SEO

Behind every successful business is a strong SEO campaign. But with countless optimization tools and techniques out there to choose from, it can be hard to know where to start. Well, fear no more, cause I've got just the thing to help. Presenting the Ranktracker all-in-one platform for effective SEO

We have finally opened registration to Ranktracker absolutely free!

Create a free accountOr Sign in using your credentials

Customer relationships suffer lasting damage from human error-induced delays. Missing delivery deadlines triggers penalty clauses worth millions. Lost contracts to more reliable competitors create revenue gaps lasting years. Brand reputation, built over decades, erodes with each shipment delay blamed on "production issues." One aerospace supplier lost a $450 million contract after repeated delays traced to human errors in their assembly processes.

Supply chain ripple effects magnify local errors into global disruptions. When a human error at a tier-two supplier delays component delivery, the impact cascades through multiple tiers, affecting dozens of companies and thousands of workers. The semiconductor industry witnessed this firsthand when operator errors at key facilities created shortages affecting everything from automobiles to consumer electronics, with economic impacts measured in hundreds of billions.

Why Traditional Approaches Fail

Organizations typically respond to human error through blame, retraining, or process modification. These reactive approaches fail because they address symptoms rather than root causes. Blaming individuals creates fear-based cultures where workers hide mistakes rather than report them, allowing small errors to evolve into major failures. Retraining assumes the problem lies with individual knowledge rather than systemic issues. Process modifications often add complexity that creates new opportunities for error.

The fundamental flaw in traditional approaches is treating human error as a people problem rather than a systems problem. Humans make mistakes, that's unchangeable. But systems can be designed to prevent errors, catch them before they cause damage, or minimize their impact when they occur. This shift from managing people to managing systems transforms how organizations approach human error reduction.

Manual processes amplify human error risk by requiring perfect execution every time. Paper-based work orders get lost, illegible handwriting causes misinterpretation, and verbal instructions create inconsistencies. Even electronic spreadsheets, while better than paper, still require manual data entry, formula maintenance, and version control that invite errors. One misplaced decimal point in a maintenance schedule spreadsheet caused a chemical plant to miss critical inspections, resulting in equipment failure costing $7.8 million.

The absence of real-time visibility means errors often go undetected until they cause failures. Managers discover problems hours or days after they occur, when correction costs have multiplied exponentially. Without systematic error tracking, organizations can't identify patterns, measure improvement, or predict where future errors might occur.

How CMMS Software Transforms Human Error Management

Modern CMMS software addresses human error through systematic prevention, detection, and mitigation rather than blame and punishment. By digitizing and standardizing maintenance processes, mpulsesoftware.com and similar platforms create error-resistant environments where doing the right thing becomes easier than making mistakes.

Automated workflow enforcement ensures critical steps can't be skipped or performed out of sequence. When technicians must complete safety checks before accessing equipment, scan barcodes to confirm correct parts, and acknowledge each procedural step, opportunities for error dramatically decrease. One food processing facility reduced human error incidents by 67% within six months of implementing workflow-enforced CMMS software.

The All-in-One Platform for Effective SEO

Behind every successful business is a strong SEO campaign. But with countless optimization tools and techniques out there to choose from, it can be hard to know where to start. Well, fear no more, cause I've got just the thing to help. Presenting the Ranktracker all-in-one platform for effective SEO

We have finally opened registration to Ranktracker absolutely free!

Create a free accountOr Sign in using your credentials

Intelligent work instructions adapt to user experience levels, equipment conditions, and historical patterns. New technicians receive detailed step-by-step guidance with images and warnings. Experienced workers see streamlined instructions focusing on critical points. The system learns from past errors, automatically highlighting steps where mistakes previously occurred. This adaptive approach reduced training time by 40% while improving task accuracy by 55% at a major automotive supplier.

Real-time error detection capabilities identify and flag anomalies immediately. When operators enter parameters outside acceptable ranges, the system alerts them before equipment starts. When maintenance tasks take significantly longer or shorter than historical averages, supervisors receive notifications to investigate. This immediate feedback loop catches errors while correction remains simple and inexpensive.

The Role of Digital Documentation and Knowledge Management

CMMS software transforms tribal knowledge into organizational assets through comprehensive documentation capabilities. Every maintenance action, every parameter adjustment, and every observed condition becomes part of searchable institutional memory. When technicians encounter problems, they access complete histories showing how similar issues were successfully resolved, what didn't work, and why specific approaches were chosen.

Video integration revolutionizes knowledge transfer between experienced and novice workers. Senior technicians record procedures while performing them, creating visual libraries that preserve decades of expertise. Augmented reality overlays guide new workers through complex tasks, showing exactly where to place tools, which bolts to tighten first, and what properly assembled components should look like. This multimedia approach reduced human error rates by 73% in complex assembly operations.

Automated documentation eliminates the inconsistencies plaguing manual record-keeping. Voice-to-text capabilities let technicians describe findings hands-free while working. Image recognition automatically identifies parts and tools. GPS tracking confirms work locations. Timestamps create indisputable audit trails. This automation not only reduces documentation errors but also increases compliance from 60% to over 95% as workers find documentation easier than avoiding it.

The collaborative knowledge base grows stronger with each use. When one technician discovers a better method, the system captures and shares it instantly across all facilities. When errors occur, root cause analyses become learning opportunities for the entire organization. Pattern recognition algorithms identify error trends before they become endemic problems.

Predictive Analytics for Human Error Prevention

Advanced CMMS software now predicts human error before it occurs by analyzing patterns across thousands of data points. Machine learning algorithms identify conditions that historically precede errors: excessive overtime leading to fatigue-induced mistakes, specific equipment combinations that confuse operators, or environmental conditions that impair judgment. These predictions enable proactive interventions that prevent errors rather than just responding to them.

Behavioral analytics track individual and team performance patterns, identifying when additional support or training might prevent errors. The system recognizes when technicians consistently struggle with specific procedures, when shifts show elevated error rates, or when certain supervisor-technician combinations produce suboptimal outcomes. This isn't about surveillance or punishment but about providing targeted support where it's most needed.

Risk scoring algorithms evaluate every work order for human error potential based on complexity, technician experience, equipment criticality, and historical error patterns. High-risk tasks automatically trigger additional safeguards: mandatory peer review, step-by-step verification requirements, or supervisor oversight. This graduated response ensures resources focus where human error would cause maximum damage.

Simulation capabilities let organizations test process changes virtually before implementing them physically. By modeling how humans interact with new procedures, equipment configurations, or production schedules, companies identify and eliminate error opportunities during planning rather than discovering them during production.

Implementation Strategies for Maximum Impact

Successfully leveraging CMMS software for human error reduction requires more than installation. Organizations must fundamentally reimagine their relationship with mistakes, shifting from blame-based cultures to learning-based environments where errors become improvement opportunities rather than career threats.

Phased implementation allows organizations to demonstrate value while building confidence. Starting with highest-risk areas where human error causes maximum damage provides immediate returns that justify broader deployment. One pharmaceutical manufacturer began with packaging lines where labeling errors risked patient safety, reducing errors by 89% before expanding systemwide.

Change management must address fear and skepticism head-on. Workers often view CMMS software as surveillance tools designed to catch and punish mistakes. Successful organizations emphasize how systems protect workers by preventing errors, provide support through better information, and eliminate frustrating paperwork. When technicians see CMMS software as assistants rather than supervisors, adoption accelerates dramatically.

Continuous improvement processes ensure systems evolve with organizations. Regular error pattern reviews identify new risk areas. User feedback drives interface improvements. Success metrics track not just error reduction but also worker satisfaction, process efficiency, and knowledge retention. This iterative approach transforms CMMS software from static tools into dynamic partners in operational excellence.

The Measurable Impact on Operations

Organizations successfully implementing CMMS software for human error reduction report transformational results extending far beyond reduced downtime. Error rates typically drop 60-80% within the first year as standardized processes and intelligent safeguards take effect. Training time for new technicians decreases by 40-50% as digital guidance accelerates competency development. Perhaps most importantly, organizational culture shifts from reactive firefighting to proactive optimization.

Financial returns justify investment many times over. Preventing just one significant human error monthly saves millions in avoided downtime. Reduced overtime, decreased scrap, and fewer warranty claims contribute additional savings. Improved customer satisfaction from reliable delivery performance creates competitive advantages worth far more than cost savings alone.

Safety improvements represent perhaps the greatest benefit. Human errors don't just stop production, they injure workers. By preventing errors, CMMS software protects people from accidents that could end careers or lives. The correlation is clear: facilities with lowest human error rates consistently achieve best safety records.

Looking Ahead: The Future of Error-Proof Manufacturing

The evolution of CMMS software continues accelerating as artificial intelligence and machine learning capabilities mature. Future systems will predict human errors with increasing accuracy, provide real-time coaching through augmented reality, and automatically adjust processes based on human factors like fatigue, stress, or distraction.

The All-in-One Platform for Effective SEO

Behind every successful business is a strong SEO campaign. But with countless optimization tools and techniques out there to choose from, it can be hard to know where to start. Well, fear no more, cause I've got just the thing to help. Presenting the Ranktracker all-in-one platform for effective SEO

We have finally opened registration to Ranktracker absolutely free!

Create a free accountOr Sign in using your credentials

Integration with wearable technology will monitor physiological indicators, alerting supervisors when conditions suggest elevated error risk. Exoskeletons will prevent physical errors by limiting incorrect movements. Brain-computer interfaces might eventually enable thought-based error checking, catching mistakes at the moment of intention rather than action.

Yet technology alone won't eliminate human error. Success requires recognizing that humans remain manufacturing's greatest asset despite being its most variable component. CMMS software succeeds not by replacing human judgment but by augmenting it, not by eliminating human involvement but by making it error-resistant.

Conclusion: From Crisis to Competitive Advantage

The $1.4 trillion lost annually to unplanned downtime represents more than financial hemorrhaging. It's symptomatic of manufacturing's failure to address its most persistent challenge: human error. While organizations chase perfect machines and flawless supply chains, they ignore the imperfect humans who ultimately determine operational success or failure.

CMMS software offers a proven path from this crisis to competitive advantage. By systematically preventing, detecting, and mitigating human error, these platforms transform manufacturing's greatest weakness into manageable risk. The technology exists, the benefits are proven, and the costs of inaction grow daily.

Organizations facing this choice should remember that every day of delay means more preventable errors, more unnecessary downtime, and more lost opportunities. While competitors implement CMMS software to build error-resistant operations, those clinging to traditional approaches will find themselves increasingly unable to compete in markets that demand both efficiency and reliability. The question isn't whether to address human error through CMMS software, but whether you'll lead this transformation or follow competitors who already have.