Intro

Tuesday morning. Conference room in Houston. VP of operations explaining why their distribution network can't handle the new markets they just entered. "We're shipping three times the volume we did last year. But cost per unit went up instead of down. Delivery times got worse. Error rates doubled. We grew, but broke everything in the process."

I've heard this story maybe twenty times in past two years. Companies hit growth targets, expand into new regions, add product lines. Then realize their supply chain can't scale at the pace their business is moving. What worked at smaller volumes falls apart when you try to grow it – systems that used to be efficient become bottlenecks, processes that made sense stop making sense. The fundamental challenge isn't technical capability but architectural thinking about how operations need to evolve as scale increases, which is why approaches like supply chain by Innovecs emphasize building flexibility and automation into the foundation rather than bolting them on later when problems emerge, because retrofitting efficiency into a system designed for different volumes rarely works as well as designing for scale from the start. Companies that understand this distinction grow smoothly. Companies that don't grow painfully.

Where scaling breaks down

Procurement director at consumer goods company told me their story last month. Three years ago: two warehouses serving eastern US. Worked fine. Then expansion hit. Now seven warehouses across North America. Should be more efficient. Instead it's chaos.

"Nobody knows where inventory actually is. Sales reps promise delivery from nearest warehouse. But that warehouse might be out of stock while another three states away has surplus. We're shipping air freight to cover gaps that shouldn't exist. Inventory carrying costs up forty percent but service levels went down."

The problem wasn't the warehouses. They scaled locations without scaling coordination systems. Each warehouse operated like its own island. No real-time visibility. No dynamic allocation based on demand patterns. Physical capacity without operational integration.

What efficiency actually means at scale

| Small scale operation | Large scale operation |

| Manual coordination works | Automation becomes essential |

| Personal relationships solve problems | Standardized processes required |

| Exceptions handled case-by-case | Systematic exception management |

| Single point of control | Distributed decision-making |

| Inventory centralized | Inventory strategically distributed |

Here's what people get wrong. They assume if something works at small volume, you just do more of it. That's not how it works. The mechanics change. Take order processing. Fifty orders daily? Manual review makes sense. Someone catches errors, flags unusual requests, applies judgment. Scale to five thousand orders and manual review becomes the bottleneck. You need automation with exception handling.

Manufacturing company example: great production scheduler personally optimized factory floor every morning. Knew every machine, every operator, every constraint. Company grew. Added second factory. Third factory. One person couldn't optimize three facilities manually. They needed scheduling software. He felt replaced initially. But became the person who designed the rules the system followed, handled truly complex exceptions, trained others. His expertise didn't become obsolete. It just worked at different level.

The integration challenge

Most scaling failures come down to integration. Companies add warehouses, suppliers, markets, product lines. Each makes sense independently. But they don't think through how everything connects. Jennifer runs logistics for food distributor. Grew from regional to national over three years. Added facilities in six states. "We thought we were being smart letting each region operate semi-independently. Local teams knew their markets."

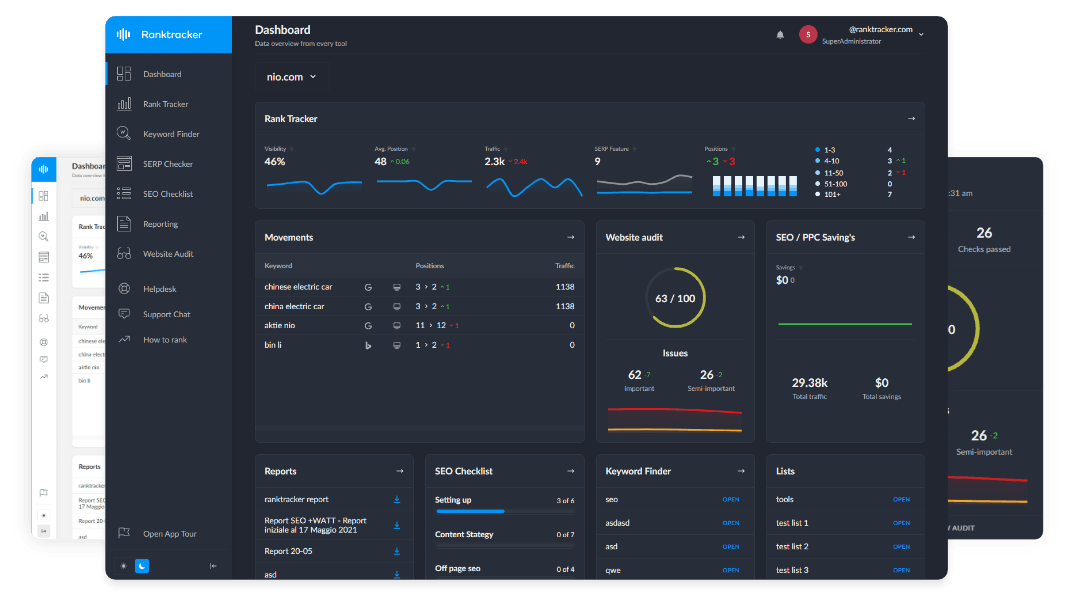

The All-in-One Platform for Effective SEO

Behind every successful business is a strong SEO campaign. But with countless optimization tools and techniques out there to choose from, it can be hard to know where to start. Well, fear no more, cause I've got just the thing to help. Presenting the Ranktracker all-in-one platform for effective SEO

We have finally opened registration to Ranktracker absolutely free!

Create a free accountOr Sign in using your credentials

Except when customers had locations in multiple regions wanting consistent service. Or supply disruptions in one region could have been solved by shifting from another. Or when negotiating better carrier rates based on total volume but couldn't because each region contracted separately.

"Seven different warehouse management systems. Four different transportation management systems. No way to see our total operation. We weren't running a national company. We were running seven regional companies that happened to share a name." Eighteen months integrating everything. Now they manage their network as a network. Inventory visibility across all locations. Dynamic routing based on total capacity. Consolidated vendor relationships. Cost per delivery down thirty-two percent while improving delivery times.

Making it work

Companies that scale successfully invest in integration before it becomes critical. They automate repetitive decisions but maintain human oversight for complex ones. They build flexibility into systems rather than optimizing for current state. They also accept things need to work differently at larger scale. The approach that got them to fifty million won't get them to five hundred million. That's evolution, not failure. Hardest part is knowing when to change. Too early and you're overbuilding. Too late and you're fixing things while they're breaking. Companies that monitor cost per unit trends, error rates, delivery variance, inventory turns usually see problems coming before crises.

The Houston VP? Six months into fixing their operation. Consolidated distribution centers from twelve to seven facilities. Implemented warehouse management with real-time inventory visibility. Standardized processes. Cost per unit down eighteen percent. Delivery times improved. Error rates dropped. Growth doesn't have to break your operation. But it will if you don't actively design for it.