Intro

Supplier and reseller relationships define the stability of global hardware operations. Weak evaluation processes cause delayed deliveries, inconsistent support, and poor coverage in key regions.

The right approach protects uptime, expands coverage, and reduces dependency on a single source. It also ensures partners can integrate with your systems and scale with your needs.

This article provides a practical framework to evaluate suppliers and resellers. You’ll learn how to build a supplier scorecard, compare sourcing models, negotiate value, diversify suppliers, and track performance over time.

Build Supplier Scorecards That Go Beyond Price

Strategic supplier evaluation drives stronger IT hardware procurement outcomes. To make decisions based on data rather than opinion, use a scorecard. It provides a clear way to measure delivery reliability, support quality, coverage, and scalability across the hardware lifecycle.

Let’s look at the key evaluation metrics and how to apply them for measurable results.

Key Evaluation Metrics for IT Hardware Suppliers

Here are the core metrics your supplier scorecard should track to guide hardware procurement decisions:

- **Uptime and delivery reliability: **Track on-time fulfillment rates for every order. Measure lead time consistency across multiple shipment types and regions. This reveals which suppliers deliver reliably under varying demand and seasonal conditions.

- **Support quality: **Record average response times for different support channels. Assess the availability of multilingual support where your teams operate. Evaluate escalation processes to confirm that urgent cases get resolved without delays.

- **Geographic coverage and local compliance capabilities: **Identify which regions each supplier can serve directly. Check for compliance with local regulations in every delivery country. It reduces the risk of customs delays and non-compliance penalties.

- **Scalability: **Measure how quickly a supplier can increase order volumes during hiring spikes. Review past performance during rapid expansion or market entry to confirm they can sustain service levels at higher demand.

How to Create and Use the Scorecard

A supplier scorecard is a structured tool that tracks vendor performance against defined criteria. It turns subjective opinions into measurable data you can compare over time.

Here’s how to build and apply one effectively:

- Assign weighted scores to each category based on priorities. For example, give delivery reliability a weight of 40%, support quality 25%, geographic coverage 20%, and scalability 15%. Adjust these weights if your current business needs to place higher value on coverage or rapid scaling.

- Collect data for each metric from actual performance records. Use order history to calculate on-time delivery percentages, support ticket logs to track response times, and contract records to confirm coverage and compliance.

- Update the scorecard every quarter to capture changes over time. This helps you spot positive trends worth rewarding or declining performance that requires corrective action.

- Connect the scorecard results to your procurement plan Use high scores to justify renewals and volume increases, and low scores to start backup sourcing or renegotiations before issues escalate.

Value-Added Resellers vs. Direct Procurement

To pick the right sourcing model, you need a clear view of how value-added resellers (VARs) compare to direct procurement.

Here’s how the two approaches differ.

Advantages and Limitations of VARs

Value-added resellers give you one contact for multiple brands. This makes communication easier and cuts the time spent managing vendors. They can also handle device imaging, asset tagging, and warranty processing. These tasks move work off your IT team and speed up deployment for new hires.

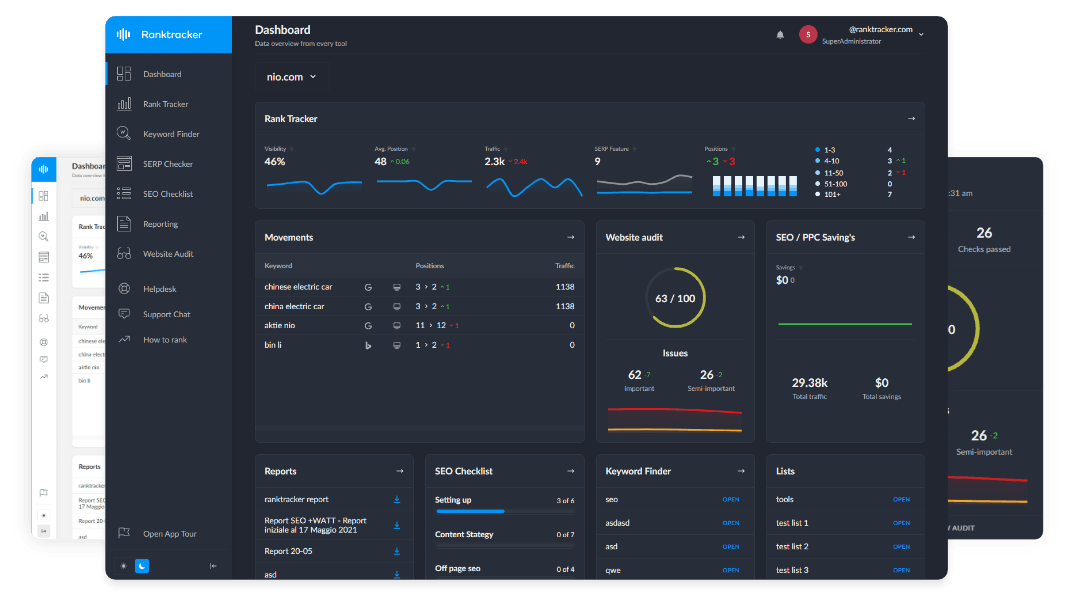

The All-in-One Platform for Effective SEO

Behind every successful business is a strong SEO campaign. But with countless optimization tools and techniques out there to choose from, it can be hard to know where to start. Well, fear no more, cause I've got just the thing to help. Presenting the Ranktracker all-in-one platform for effective SEO

We have finally opened registration to Ranktracker absolutely free!

Create a free accountOr Sign in using your credentials

The main trade-off is cost. VAR pricing includes services like device imaging, asset tagging, and warranty processing. If this model fits your needs, look for the best value-added resellers who can provide consistent service in every location.

Advantages and Limitations of Direct Procurement

Direct procurement works well when you buy large volumes of the same devices. Bulk orders can lower unit costs and simplify hardware planning.

It also fits if your in-house IT team can manage imaging, configuration, and warranty coordination. Handling these tasks internally removes the need to pay a reseller. Strong relationships with original equipment manufacturers can provide better pricing and priority support.

The main limitation is the workload on your IT team. Managing vendor accounts, tracking warranties, and preparing devices all take time. Smaller teams or fast-growing companies may struggle to keep these processes.

Negotiate IT Hardware Contracts for Long-Term Value

A 2025 survey found most procurement leaders faced recent supplier disruptions. Strong contract terms beyond price are now critical for protecting hardware operations.

Here are key factors to include when negotiating with suppliers.

Warranties and Coverage for Full Hardware Lifecycle

Hardware failures during active projects can derail timelines and increase replacement spending. Securing warranty coverage for the full lifecycle protects budgets and reduces unexpected downtime.

For distributed teams, extended warranties bring consistency across locations, even when repair capabilities or timelines differ.

Replenishment Commitments for Critical Stock

Running out of standard-issue devices delays onboarding and leaves teams without the tools they need. Firm replenishment agreements guarantee that high-demand hardware is restocked within set timelines.

Written commitments on lead times and quantities give you a clear recovery plan during demand surges or shortages.

Service-Level Agreements (SLAs) for Delivery and Support

Slow deliveries and delayed support responses disrupt operations and frustrate end users. Service-level agreements set measurable targets for delivery speed and support response. Linking these targets to penalties and rewards builds accountability. It also keeps performance aligned with business needs.

Flexible Payment Terms for Budget Alignment

Upfront hardware costs can strain quarterly budgets and limit cash flow for other priorities. Negotiating payment terms that align with budget cycles spreads costs over time.

The All-in-One Platform for Effective SEO

Behind every successful business is a strong SEO campaign. But with countless optimization tools and techniques out there to choose from, it can be hard to know where to start. Well, fear no more, cause I've got just the thing to help. Presenting the Ranktracker all-in-one platform for effective SEO

We have finally opened registration to Ranktracker absolutely free!

Create a free accountOr Sign in using your credentials

Options like staged payments or post-delivery invoicing make spending predictable and easier to manage.

Diversify Suppliers to Avoid Single Points of Failure

Relying on one supplier leaves your hardware operations vulnerable to disruptions. A diversified network lowers the risk of shipping delays, political instability, or sudden vendor changes.

Here’s how to build a resilient sourcing strategy:

- Keep at least two qualified suppliers for each major device category to maintain a backup when one vendor cannot fulfill orders.

- Use regional alternates for shipping routes vulnerable to geopolitical tensions or severe weather to keep deliveries on track.

- Maintain contingency plans for supplier insolvency or withdrawal by identifying replacement vendors in advance for fast, controlled transitions.

Ensure Integration With Your Lifecycle Stack

Disconnected systems slow hardware operations and increase costs. Integrating procurement tools with asset, tracking, and support systems keeps the hardware lifecycle aligned. It also provides one source of truth for device status, budgets, and supplier performance.

APIs link your procurement platform to lifecycle tools. This removes manual updates and reduces tracking errors. Automated reporting gives real-time visibility from purchase to end-of-life. It highlights delays, upcoming replacements, and warranty deadlines.

Accurate, up-to-date information supports proactive decisions in your procurement plan. With full visibility into device location and performance, you can schedule replacements, forecast budgets, and negotiate supplier terms.

Spot Red Flags Early in Vendor Performance

Supplier problems can start small and grow into missed deadlines, higher costs, and operational gaps. Tracking early warning signs helps you act before they affect your hardware operations.

The All-in-One Platform for Effective SEO

Behind every successful business is a strong SEO campaign. But with countless optimization tools and techniques out there to choose from, it can be hard to know where to start. Well, fear no more, cause I've got just the thing to help. Presenting the Ranktracker all-in-one platform for effective SEO

We have finally opened registration to Ranktracker absolutely free!

Create a free accountOr Sign in using your credentials

For example, an increase in backorders without a recovery plan signals supply problems or poor inventory management. When shortages persist, onboarding slows, and teams may need hardware from untested vendors at short notice.

Backorder issues can also lead to wider service disruptions. Declining SLA performance or more support tickets show supplier capacity or focus is slipping. Missed deliveries, delays, and unresolved issues disrupt deployments and reduce satisfaction.

Service breakdowns may stem from instability inside the supplier’s organization. Unexplained staff changes or sudden contract revisions can signal deeper challenges. Frequent turnover disrupts communication, and unexpected contract changes damage trust.

Bottom Line

Supplier and reseller decisions shape the stability of your hardware operations. The right partners can support growth, adapt to change, and protect against operational risk. Meanwhile, poor choices can cause delays, unexpected costs, and avoidable disruptions.

Strong evaluation practices give you leverage to secure better terms, build sourcing resilience, and align suppliers with business goals. Treat vendor management as ongoing, and adjust your approach as operational needs change.