Intro

Ever felt like your maintenance team is always playing catch-up? Breakdowns happen without warning, tasks fall through the cracks, and managing it all with spreadsheets or paper checklists just adds to the chaos. That's where CMMS steps in. But let's start with the basics: What does CMMS actually mean, and why does it matter to your operations?

If you've been hearing the term "CMMS" tossed around in maintenance meetings or while exploring new tools, understanding the CMMS meaning is the first step to transforming how your team operates.

CMMS Meaning: What It Stands For—and What It Stands For in Practice

CMMS stands for Computerized Maintenance Management System. It's a type of software that helps organizations plan, track, and optimize maintenance activities. But it's more than just a digital filing cabinet.

A CMMS allows maintenance managers and technicians to:

- Create and manage work orders

- Schedule preventive maintenance

- Track inventory and parts usage

- Monitor equipment performance

- Generate reports to improve operations

The result? Less downtime, more accountability, and better asset performance across the board.

Why CMMS Is No Longer a "Nice-to-Have"

Let's face it—equipment doesn't break down when it's convenient. It breaks down when your team is already overloaded or when you're short on supplies. Without a centralized system to manage maintenance, things get missed—and that costs money.

The U.S. General Services Administration (GSA) reports that implementing a digital maintenance program, like CMMS, can reduce overall maintenance costs by up to 20% while improving asset reliability. That's a big deal when you're trying to maintain safety, meet production goals, and stay within budget.

And it's not just about preventing breakdowns. A CMMS improves communication, reduces paperwork, and ensures every team member knows what to do and when to do it.

Everyday Benefits of Using a CMMS

Imagine this: You manage a team of 10 technicians at a large facility with hundreds of assets. Without a CMMS, you're juggling requests from different departments, manually tracking maintenance logs, and hoping your team remembers upcoming inspections.

With a CMMS, you can:

- Automatically assign tasks based on availability and skill.

- Get real-time updates on task progress.

- Track parts usage to avoid stockouts.

- Access equipment history in seconds.

This kind of visibility gives you more control—and your technicians more clarity.

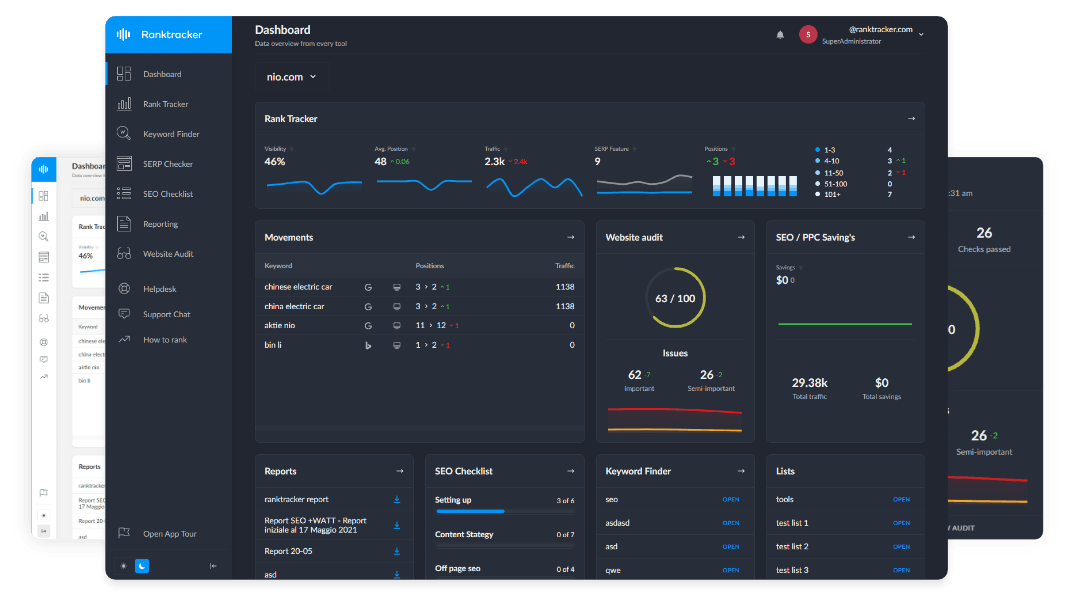

The All-in-One Platform for Effective SEO

Behind every successful business is a strong SEO campaign. But with countless optimization tools and techniques out there to choose from, it can be hard to know where to start. Well, fear no more, cause I've got just the thing to help. Presenting the Ranktracker all-in-one platform for effective SEO

We have finally opened registration to Ranktracker absolutely free!

Create a free accountOr Sign in using your credentials

In sectors like manufacturing, education, hospitality, and facilities management, these benefits lead to smoother operations, better safety compliance, and improved customer satisfaction.

Choosing the Right CMMS: What to Look For

When it comes to picking a CMMS, focus on features that make your team's life easier and your workflow more efficient. Look for:

- Simple interface – If it's hard to use, no one will use it.

- Mobile capability – Your team should be able to log tasks from the field.

- Custom scheduling tools – Flexible calendars keep PMs on track.

- Smart reporting – Real-time data helps you make smarter decisions.

- Support and onboarding – Choose a provider that helps you every step of the way.

Still Managing Maintenance on Spreadsheets?

If you're using spreadsheets, sticky notes, or email threads to track maintenance, you're not alone—but there's a better way. A CMMS helps reduce human error, speeds up maintenance response times, and gives you peace of mind.

It also means fewer emergency repairs, better team coordination, accurate audit trails for compliance, data-driven decisions instead of guesswork, and when you track everything in one place, you can spot trends—like which machines need extra attention or which locations are underperforming.

The Bottom Line

Understanding the CMMS meaning goes beyond just knowing what the letters stand for. It's about recognizing the real impact this tool can have on your day-to-day operations.

From reducing equipment downtime to making your team more efficient, a CMMS is a smart investment for any business that relies on assets, systems, or facilities.

If you're ready to cut down on reactive maintenance and take control of your operations, a CMMS might just be the game-changer you've been waiting for.

Let your maintenance team do what they do best—without the guesswork.